Ozone aging test chamber can be used for rubber products with static & dynamic tensile deformation such as vulcanized rubber, thermoplastic rubber, cable insulation jacket and other products,expose the test specimens to the sealed air in the test chamber without light and with constant ozone concentration and constant temperature according to predetermined time, and then observe the cracks on test specimens’ surface and the change degree of other properties to evaluate the rubber’s ozone aging resistance properties.

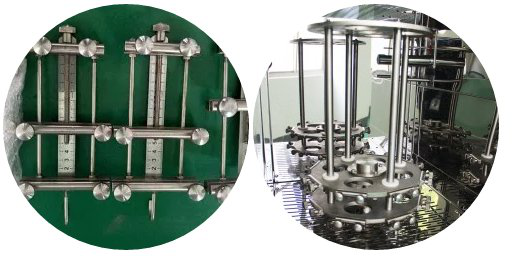

Shanghai Linpin Instrument Co.Ltd have rich experience in environmental test chamber ,You can visit our website ,Facebook, Linkedin,Twitter, Youtube and any other information from website .If you are free welcome to visit our company and factory. Today I would like to introduce our Ozone aging test chamber to help all of us reference and purchase , There are two types chamber according to different sample holder, static ozone test chamber(static tensile sample holder ) and dynamic ozone test chamber(dynamic tensile sample holder-360 degree rotating).

LENPURE would like to provide On-site service and OEM/ODM service to our all customer, If you have any special requirements ,please contact us or call us: sales@lenpure.com/021 31396828

1.What is our standard technical specification of Ozone test chamber?

Temperature Range :25℃~65℃(Adjustable)

Humidity Range:40~95%RH

Temperature Fluctuation:±0.5℃when unloading

Temperature Uniformity:≤2℃when unloading

Temperature Deviation: when ≤75%RH,±5%RH / when >75%RH,+2%、-3%RH

Temperature ramp rate :±2℃

Air Flow Rate:8~16mm/s (customized)

Ozone concentration deviation:≤±10%

Rotate speed of test specimen fixture:1~3R/min(adjustable)

Time setting Range :1~9999H

2.Source of ozonized air

The ozonized air shall be largely free of nitrogen oxides in order to avoid errors in the ozone concentartion. One of the following items of apparatus shall therefore be used

A)Ultra-ciolet lamp

B)Silent discharge tube

3.Test pieces of Ozone test chamber

Test pieces shall be cut from moulded sheet, or if required, form a finished product,in accordance with ISO 23529.Test pieces shall have an undamaged test surface, ozone resistance shall bot be assessed on surfaces that have been cut or buffed.Comparisons of different materials are only valid if the cracking is assessed on surfaces of similar finish produced by the same method.

For each set of test conditions, at lease three test pieces shall be used

A)Wide test piece

This test piece shall consist of a strip of not less than 10mm in width, of thickness2.0mm0.2mm and of length not less than 40 mm between the grips before stretching.

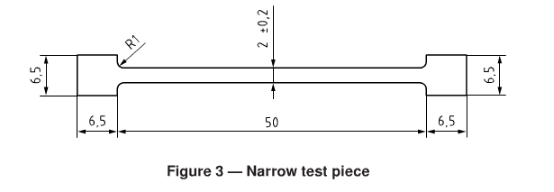

B)Narrow test piece

This test piece shall consist of a strip of width 2.0±0.2mm,thickness 2.0±0.2mm and length 50mm, between enlarged tab ends 6.5mm square.

Dumb bell test pieces in accordance with ISO 370 may also be used

4.Ozone concentration

Low Concentration 50~1000pphm

high concentration 50~300ppm(customer could choose either.)

5.Test Standard of Ozone aging test chamber

ISO 1431→Rubber, vulcanized or thermoplastic- resistance to ozone cracking- part1: static and dynamic strain test

ASTM D1149-2007→Rubber deterioration- cracking in an ozone controlled environment

BS 903 Part A43-1990→Method for determination of resistance to ozone cracking

JIS K6259-2004→Rubber, vulcanized or thermoplastic- resistance to ozone cracking- part1: static strain test

GB/T 7762-2003→Rubber , vulcanized or thermoplastic - resistance to ozone cracking - static strain test method

GB/T 2951.1-2951.10-1997→Common test methods for insulating and sheathing materials of electric cables

Warning-Attention is drawn to the highly toxic nature of ozone.