Environmental Test Chambers for IEC 60068-2-5

Shanghai Lenpure Company Air-cooled Xenon Aging Environmental Test Chamber adopts xenon arc-lamp which can realize full wavelength of natural sunlight to the most extent, so that to reappear destructive light radiation of different environment. Also can simulate rainfall, high & low temperature and moisture of natural environment, so that it can perform extremely realistic accelerated weathering test on material and coating layer.

Feature

▪High performance and quiet operation (20~ 70 dBa).

▪Touch-screen controller, user-friendly.

▪Import Q-Lab air-cooled Full spectrum xenon lamp, more economical, more efficient and easier to maintain. Lamp life of 1800 hours.

▪The flat sample mounting tray can accommodate different shapes and sizes of samples, including 3D parts. There are a variety of sample stents to choose from.

▪The irradiance control system continuously monitors and controls the output of the light, which ensures accurate exposure and repeatable test results.

▪Allows the user to simultaneously control and monitor relative humidity, blackboard temperature and air temperature in the box.

▪All circuits fused or circuit breaker protected, overload protection.

▪All wiring numbered or color coded.

▪ Tri-color Indicator and EMO (Emergency-off Switch) available.

Test Standards

IEC 60068-2-5

ISO 4892-2 / ISO 3917 / ISO 11341 / ISO 105-B02/06 / ISO4665-3

JISK 6781

UL 62275

This test equipment comply with above test standards (but not limited to).

This part of IEC 60068 describes methods of simulation designed to examine the effect of solar radiation on equipment and components at the surface of the earth. The main characteristics of the environment to be simulated are the spectral energy distribution of the sun, as observed at the earth's surface, and the intensity of received energy, in combination with controlled temperature conditions. However, it may be necessary to consider a combination of solar radiation with other environments, e.q. temperature, humidity, air velocity, etc.

This part of IEC 60068 provides guidance for testing equipment or components under solar radiation conditions.The purpose of testing is to investigate to what extent the equipment or components are affected by solar radiation.The method of combined tests detects electrical, mechanical or other physical variations.

During the entire test, the irradiation, the temperature within the chamber, the humidity and any other specified environmental conditions shall be maintained at the levels appropriate to the particular test procedure specified in the relevant specification. The relevant specification shall state which preconditioning requirements are to be applied.

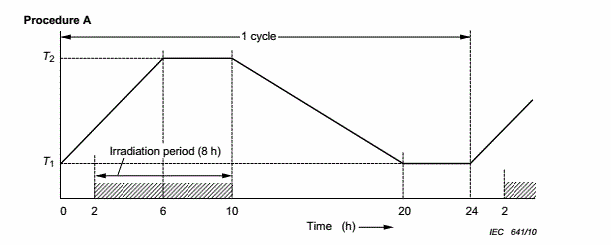

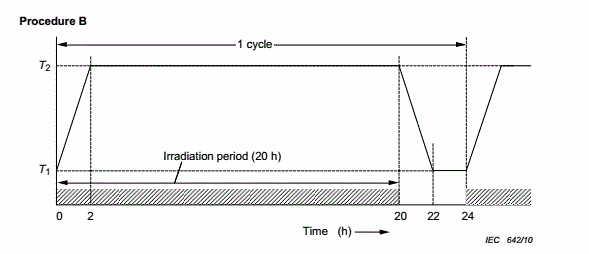

The temperature within the chamber during irradiation and darkness periods shall be controlled in accordance with the procedure (A, B or C) specified. During irradiation, the temperature within the chamber shall rise or fall by 1 K/min and be maintained at one of the preferred "values given in IEC 60068-2-1, IEC 60068-2-2 or the relevant specification.

Different humidity conditions, particularly condensation, can markedly affect photochemical degradation of materials, paints, plastics, etc. If required, the values of IEC 60068-2-78 shalll be preferred.

The relevant specification shall state the humidity and whether it is to be maintained during:

a) the irradiation periods only:

b) the periods of darkness only;

c) the whole test duration.

The chamber in which the tests are to be carried out shall be provided with means for obtaining, over the prescribed irradiation measurement plane, an irradiance of 1 120 W/m2 ± 10 % with the spectral distribution given in Table 1. The value of 1 120 W/m2 shall include any radiation reflected from the test chamber and received by the specimen under test. It should not include long-wave infra-red radiation emitted by the test chamber.

Means shall also be provided whereby the specified conditions of temperature, air flow and humidity can be maintained within the chamber.

The temperature within the chamber shall be measured (with adequate shielding from radiated heat) at a point or points in a horizontal plane 0 mm to 50 mm below the prescribed irradiation measurement plane, at half the distance between the specimen under test and the wall of the chamber, or at 1 m from the specimen, whichever is the lesser.

During exposure, the temperature within the chamber shall rise or fall by 1 K/min and be maintained at one of the preferred values given in IEC 60068-2-1 or IEC 60068-2-2 or the relevant specification.

In procedure A, the temperature within the chamber shall start to rise 2 h before the irradiation period starts.

During the darkness period in procedures A and B, the temperature within the chamber shall fall approximately with 1 K/min and be maintained at +25 C. If the required temperature is lower than 25 C. the temperature shall be maintained at the required temperature.

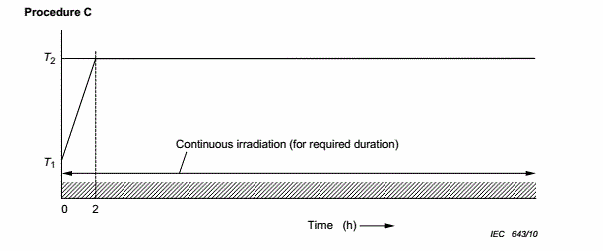

The requirements for irradiation, temperature and time relationships are given in Figure 2.Throughout the specified test duration, the temperature within the chamber shall be maintained within 2 C of that shown for the appropriate procedure.

The level of irradiance should be 1 120 W/m2 ± 10 % or specified in the relevant specification.Acceleration of the test by increasing the irradiation above this level is not recommended. The total daily irradiation approximating the most severe natural conditions is simulated by procedure A with a duration of exposure to the standard irradiation conditions of 8 h per day.

Thus, exposure for periods in excess of 8 h will effect acceleration over natural conditions.However, continuous exposure of 24 h per day, procedure C, might mask any degradation effects of cyclic thermal stressing, and this procedure is therefore not generally recommended in this instance.

The specimen shall be exposed, for the duration called for in the relevant specification, to one of the following test procedures.

Procedure A-24 h cycle, 8 h irradiation and 16 h darkness, repeated as required

This gives a total irradiation of 8,96 kWh/m2 per diurnal cycle, which approximates to the most severe natural conditions. Procedure A should be specified where the principal interest is in thermal effects.

This gives a total irradiation of 22,4 kWh/m2 per diurnal cycle and is applicable where the principal interest is in degradation effects.

A simplified test, applicable where cyclic thermal stressing is unimportant and photochemical effects only are to be assessed. Also for the assessment of heating effects on specimens with low thermal capacity.

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or our company, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .