Climatic chambers ASTMD 4329 UV aging test

Lenpure UV-Lamp Weathering Test Chamber Take fluorescent UV lamp as light source to simulate the UV irradiation in natural light and condensation to conduct accelerated weathering test to the materials. It can simulate the UV, rain, high temperature, high humidity, condensate, darkness and other environmental conditions in natural climate and combine them in a circle, and carry out these circles automatically.

Feature

▪Black Panel Temperature (BPT) Control

▪Touch-screen controller, user-friendly

▪With irradiance monitor function

▪Import Q-Lab air-cooled UV lamp, more economical, more efficient and easier to maintain. Lamp life of 1800 hours.

▪Door Safety and Over-temperature Shutoff

▪The irradiance control system continuously monitors and controls the output of the light, which ensures accurate exposure and repeatable test results.

▪Allows the user to simultaneously control and monitor relative humidity, blackboard temperature and air temperature in the box.

▪All circuits fused or circuit breaker protected, overload protection.

▪CE Compliance and UL & CSA Certified

▪ Tri-color Indicator and EMO (Emergency-off Switch) available.

The aging test box is used by the manufacturer to realize the process of strengthening the condition of the product by various factors involved in the actual use of the product. The test is mainly aimed at the plastic material, the common aging is light aging, damp heat aging, hot air aging. In order to make the aging test box more safe to use and longer service life. Here are some of the things that should be noted and maintained:

1. A dedicated person shall be in charge of the use of the aging test box to cut off the external power supply of the equipment after the completion of the test.

2. Do not place test samples too closely in the work room, which will affect the normal flow of airflow in the work room, resulting in failure to achieve the test results. When placing the test samples, do not extend the test samples into the indoor wind blade barrier to avoid causing accidents.

Please do not remove the power supply and parts of the equipment at will, avoid damage to the electrical control line and the human accident of the equipment, affect the normal performance of the work, in the door lock, do not pull the door handle, to prevent damage to the door lock device.

Clean the surface of the aging test box with neutral detergent, then clean with clean water and dry with clean cloth.

During the maintenance of the aging test box, please cut off the external power supply of the equipment to avoid electric shock.

| Model | Volume (L) |

Temperature Range (°C) |

Rated Power | Internal Dimension (mm) D*W*H | External Dimension (mm) D*W*H |

| LRHS-NZY | 263 | RT+10°C ~ 70°C | 4kw | 450*1170*500 | 680*1420*1510 |

| Basic Specification | |||||

| Performance | Temperature Range | RT+10°C ~ 70°C | |||

| Temperature Fluctuation | ±0.5°C | ||||

| Temperature Uniformity | ≤2.0°C | ||||

| Blackboard / Black Standard Temperature | 60°C ~ 100°C | ||||

| Humidity Range | ≥95%RH | ||||

| Distance between sample and lamp | 50mm | ||||

| UV Lamp Brand | Q-Lab , UV-A / UV-B | ||||

| UV Lamp power | 40W/ Pc | ||||

| Wave Length | 290nm ~ 400nm | ||||

| Radiation Indensity | ≤550W/m2 | ||||

| Simulate Condensation Time Range | 1~9999H adjustable | ||||

| Sample holder size | 365*75mm | ||||

| Sample holder Qty | 24 unit | ||||

| Material | External Casing | Cold-rolled A3 (Q235) steel plates with plastics painted. | |||

| Interior Working Room | Stainless Steel Plates SUS304 with miror surface | ||||

| Casters | 4pcs, with PU covered for protection. Height adjustable and direction universal. | ||||

| Door | Manually operated sliding door with unlock button | ||||

| Control System | Heater | Steipped Nickel-chromium Wire Heater | |||

| Controller |

7" Programmable colorful touch-screen display LCD English Display Microcomputer integrated controller |

||||

| Standard Configuration | UV-A or UV-B x 8 , Specimen Holder x 1 unit (24 pcs) | ||||

| Safety Protection | Power leakage protection, over-load or over-current protection/Dry burning protection. | ||||

| Voltage | AC220V/380V/440V±10%, 50Hz/60Hz or as per requirement | ||||

| Ambient Enviromental for application | 5°C~+30°C ≤ 85% R.H | ||||

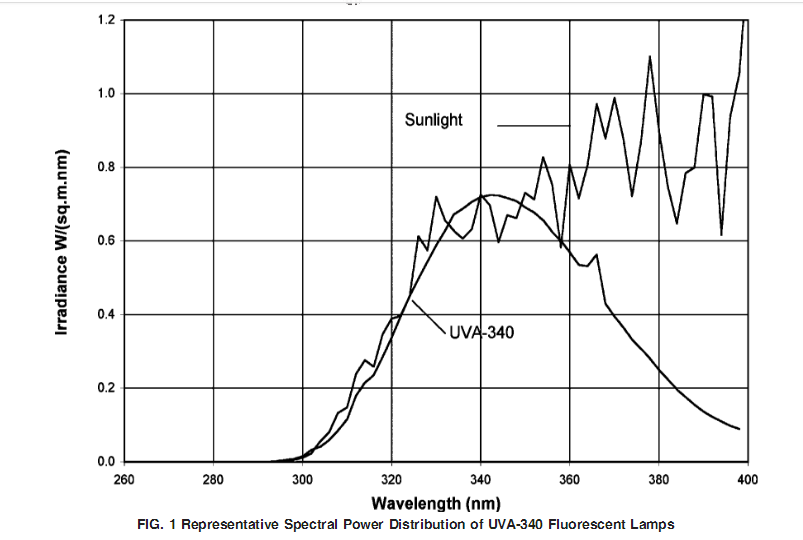

The UV-aged test chamber uses a UVA 340 lamp tube whose spectral irradiance is shown below:

1.Temperature in the box

The temperature in the box should be controlled by the specified test procedure (A, B, or C) during the irradiation phase or the stopping phase. The relevant specifications should specify the temperature to be reached during the irradiation phase +40 degrees or +55 degrees according to the intended use of the equipment or component .

2.Airflow speed

In addition to affecting the temperature rise of the sample, the velocity of the air flow near the sample surface can even cause a significant error in the open-type temperature difference reactor that monitors the radiation intensity. Generally, the speed of 1m / s causes the temperature rise of the thermoelectric reactor to decrease by more than 20%. It can be seen that while effectively controlling the temperature or conditions in the box, the air velocity should be monitored and the lowest possible speed should be used. In addition, when adjusting the temperature in the box, high-speed airflow can be avoided by heating or cooling the box wall.

In the natural environment, the probability of the occurrence of strong solar radiation and the special condition of zero wind speed is extremely small. Therefore, when the impact of different wind speeds on equipment or components and other samples needs to be evaluated, the relevant specifications should specify specific requirements.

3.Surface pollution

Dust and other surface contaminants will severely alter the absorption characteristics of the surface of the illuminated object. Unless otherwise specified, the sample should be kept clean during the test, but when assessing the effect of surface contamination, relevant specifications should specify the necessary content of the surface treatment of the sample.

4.Humidity

Under different humidity conditions, the photochemical degradation effects of various materials, coatings, and plastics are extremely different, and their requirements for humidity conditions are different from each other, so the specific humidity conditions are clearly specified by relevant regulations. For example, the test program B is prescribed to be carried out under the hot and humid conditions (40 degrees, relative humidity 93%) at the beginning of each cycle.

5. Ozone and other polluting gases

The ozone produced by the cabinet under the short-wave ultraviolet radiation of the light source can usually be discharged out of the test chamber through a radiation filter that corrects the spectral energy distribution. Ozone and other pollutant gases will affect the degradation process of certain materials, unless the relevant specifications otherwise It is stipulated that these harmful gases must be discharged out of the box.

6.Bracket and its installation

The thermal characteristics of various brackets and their installation methods will seriously affect the temperature rise of the test sample, which should be fully considered so that its heat transfer characteristics represent typical actual use cases. During the test, most of the samples are mounted on various elevated supports or cushions that specifically specify the thermal characteristics. Detailed requirements regarding the cushions and their installation methods and sample placement should be relevant.

More details, Please feel free to contact sales@lenpure.com

Or visit www.lenpure.com