Climate Chambers for IEC 60068-2-14 Environmental Testing Prat2-14: Tests: Test N: Change of Temperature

Shanghai Linpin company has just developed a few of new environmental test chambers, and now it is your job to select an environmental test chamber to test it. The climate chamber must be tested at various conditions to ensure its quality and reliability. Where do you start? What will determine your selection criteria? Price, quality, capabilities…....As with any major purchase, several items must be considered before making the final decision. Many people are tempted to buy on price only. However, as we know, you get what you pay for.

Quality, reliability, and service after the sale all add up to the value of your purchase. Value often is mistaken for low price. Over the life of the unit, that can become a costly mistake. Many different types of environmental test chambers are available. Your application is primarily going to determine the type of environmental test chambers you need.

The better you relay that information to your supplier, the better your climate chamber will match your needs. Such as: How big must the climate chamber be? What is being tested? Is it going to be air cooled or water cooled? What temperature range is needed? These are just a few of the necessary questions that must be answered before purchasing a test chamber.

As is well-known, a change of temperature test is intended to determine the effect on the specimen of a change of temperature or a succession of changes of temperature. It is not intended to show effects which are due only to high or low temperatures. For these effects, the dry heat test or the cold test should be used.

The effect of such tests is determined by:

the values of high and low conditioning temperature between which the change is to be effected;

the conditioning times for which the test specimen is kept at these temperatures;

the rate of change between these temperatures;

the number of cycles of conditioning;

the amount of heat transfer into or from the specimen.

Guidance on the choice of suitable test parameters for inclusion in the detail specification is given throughout this standard.

If you still fully don't know how to choose environmental test chambers, you can also choose according to the test sample or test criteria, such as IEC 60068-2-14, today I will tell you about the test standard of IEC 60068-2-14. International Standard IEC 60068-2-14 has been prepared by IEC technical committee 104: Environmental conditions, classification and methods of test.

This part of IEC 60068 provides a test to determine the ability of components, equipment or other articles to withstand rapid changes of ambient temperature. The exposure times adequate to accomplish this will depend upon the nature of the specimen.

Field conditions of changing temperature

It is common in electronic equipment and components that changes of temperature occur.Parts inside equipment undergo slower changes of temperature than those on an external surface when the equipment is not switched on.

Rapid changes of temperature may be expected:

when equipment is transported from warm indoor environments into cold open air conditions or vice versa;

when equipment is suddenly cooled by rainfall or immersion in cold water;

in externally mounted airborne equipment;

under certain conditions of transportation and storage.

Components will undergo stresses due to changing temperature when high temperature gradients build up in an equipment after being switched on, e.g. in the neighbourhood of high wattage resistors, radiation can cause rise of surface temperature in neighbouring components while other portions are still cool.

Artificially cooled components may be subjected to rapid temperature changes when the cooling system is switched on. Rapid changes of temperature in components may also be induced during manufacturing processes of equipment. Both the number and amplitude of temperature changes and the time interval between them are important.

General

Design of change of temperature tests

Tests Na. Nb and Nc comprise alternate periods at a high and at a low temperature with well defined transfers from one temperature to the other. The conditioning run from laboratory ambient to the first conditioning temperature, then to the second conditioning temperature, then back to laboratory ambient is considered one test cycle.

Test parameters

Test parameters comprise the following:

laboratory ambient;

high temperature;

low temperature;

duration of exposure;

transfer time or rate of change;

number of test cycles.

The high and low temperatures are understood to be ambient temperatures which will be reached by most specimens with a certain time-lag.

Only in exceptional cases may they be specified outside the normal storage or operating temperature range of the object under test.The test is accelerated because the number of severe changes of temperature in a given period is greater than that which will occur under field conditions.

Purpose and choice of the tests

Change of temperature testing is recommended in the following cases:

evaluation of electrical performance during a change of temperature, Test Nb;

evaluation of mechanical performance during a change of temperature, Test Nb;

evaluation of electrical performance after a specified number of rapid changes of temperature, Test Na or Test Nc;

evaluation of the suitability of mechanical components, and of materials and combinations of materials to withstand rapid changes of temperature, Test Na or Test Nc;

evaluation of the suitability of construction of components to withstand artificial stressing, Test Na or Test Nc.

The change of temperature tests specified in the IEC 60068 series is not intended to evaluate the difference in material constants or electrical performance when operating under temperature stability at the two extremes of temperature.

Choice of the duration of the exposure

The duration of the exposure should be based on the requirements stated in 7.2.3. 8.2.3 on9.2.2. or as stated in the relevant specification, keeping in mind the following points:

a) The exposure begins as soon as the specimen is in the new environment.

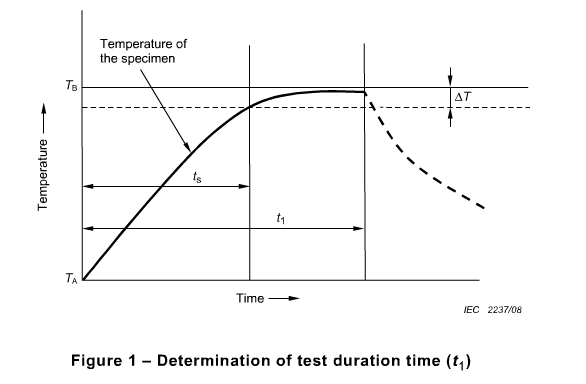

b) Stabilization occurs when the temperature difference (△T) between the specimen and the test medium is within 3 K to 5 K, or as stated in the test specification. The stabilization period, (ts) is from the start of exposure until the time when the temperature is within the specified difference. A representative point (or points) on the specimen may be used for this measurement.

c) The test duration, t1, shall be longer than the specimen stabilization time, ts. Figure 1 provides a graphical representation of the process. This may not be appropriate for heat generating specimens.

Choice of the duration of the transfer time

If, in the case of the two-chamber method. because of the large size of the specimens the transfer time cannot be made in 3 min, the transfer time may be increased without an appreciable influence on the test results as follows:

T2≤0.05Ts

Where

T2 is the duration of the transfer time

Ts is the stabilisation period of the specimen

Applicability limits of change of temperature tests

Inside a specimen, the temperature change rate depends on the heat conduction of its materials, the spatial distribution of its heat capacity and its dimensions.

The change of temperature at a point on the surface of a specimen follows approximately an exponential law. Inside large specimens, such alternate exponential rises and decreases may lead to periodic and approximately sinusoidal changes of temperature with much lower amplitudes than the applied temperature swing.

The mechanism of heat transfer between the test specimen and the conditioning medium in the chamber or bath should be taken into account. Liquid in motion leads to very high rates of change of temperature on the surface of the specimens and still air to very low rates.

The two-bath method with water as a conditioning medium (Test Nc) should be restricted to specimens which are either sealed or are by their nature insensitive to water, since their performance and properties may deteriorate by immersion.

In particular cases, such as with specimens sensitive to water, a test with liquid other than water may need to be specified. When designing such a test, the characteristics of heat transfer of the liquid, which may differ from those of water, shall be taken into account.

Guidance for the selection of the kind of test

The severity of the test will increase with the increase in the temperature difference, the increase in rate of temperature change, and the heat transfer to the specimen.

The application of Tests N is preferred as part of a sequence of tests. Some types of damage may not become apparent by the final measurements of a Test N, but may appear only during subsequent tests (e.g. Test Q: Sealing, Test F: Vibration or Test D: Accelerated damp heat).

The change of temperature Test Nc (Two-bath method) should not be used as an alternative to Test Q (Sealing).

When specifying a change of temperature test, the properties of the objects under test which are affected by conditions of changing temperature, and their possible failure mechanism should be kept in mind. The initial and the final measurements should be specified accordingly.

Initial and final measurements

Tests Na. Nb and Nc all use the same initial and final measurements.

Initial measurements

The specimen shall be visually examined and electrically and mechanically checked as required by the relevant specification.

Final measurements

The specimen shall be visually examined and electrically and mechanically checked, as required by the relevant specification.

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or our company, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .