Environmental test chambers for IEC 60068-2-40 Test Z/AM: Combined cold/low air pressure tests

This publication deals with combined cold(with gradual change of temperature) and low air pressure tests for both heat-dissipating and non-heat-dissipating specimens. To reach the specification of low temperature and low air pressure, you need a climatic chamber such as our programmable temperature humidity altitude test chamber.

The object of the test is to determine the ability of components or equipment or other articles to be stored and used under a simultaneous combination of low temperature and low air pressure.

This combined test should normally be used only if the effects of combined environments will not be revealed by subjecting the specimen to single environments. The procedures given in this publication are limited to the case of specimens which achieve temperatures stability during the test procedure. In the case of testing heat-dissipating specimens, this procedure applies only to the testing of one specimen at a time.

The test procedure applies to air pressure down to about 10 mbar. At air pressure below 10 mbar, phenomena not taken into account in the design of this test procedure become important. The relationship between altitude, pressure and temperature has not been indicated in this publication. Such data should be obtained from special publications.

The guidance given in the introduction to Publication on 68-2-1,Test A: Cold, for the application of tests for non-heat-dissipating specimens versus tests for heat-dissipating specimens shall apply. Heat-dissipating specimens should preferably be tested with no forced air circulations as for Tests A: Cold.

To provide a standard test procedure to determine the suitability of components, equipment or other articles for use and/or storage under a combination of low temperature and low air pressure.

This test is a combination of Test Ab or Ad: Cold, and Test M: Low air pressure. This specimen is first subjected to the appropriate severity of cold as indication in the relevant specification. In the case of operational tests, a check is then made to ensure that the specimen is capable of operation. With the temperature maintained at the indicated value, the chamber air pressure is then reduced to the appropriate severity as specified in the relevant specification.

These conditions are maintained for the specified duration. Test profiles illustrating the procedure are shown in Figure 1a and Figure 1b. The chamber shall be capable of maintaining the conditions specified for Test Ab( for non-heat-dissipating specimen) or Test Ad(for heat-dissipating specimen) and for Test M. The requirement for the chamber wall temperature does not apply during periods of temperature or pressure change.

Care shall be taken to avoid air contamination by ancillary equipment and devices and by the air introduced when pressure is restored to normal. For the testing of a heat-dissipating specimen, the mounting of the test specimen shall comply with the requirements for Test Ad.

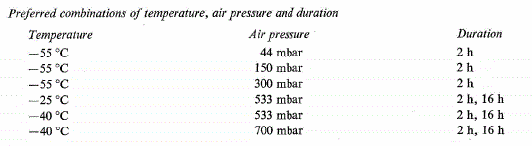

The severities, as indicated by temperature, air pressure and duration of exposure, shall be specified in the relevant specification. The temperature and low air pressure values, tolerances and durations shall be comply with those given in Test Ab or Ad and M. The duration of exposure shall be measured from the time when temperature stability of the specimen has been reached under conditions of low air pressure.

This test is a combination of Test Ab or Ad: Cold, and Test M: Low air pressure. This specimen is first subjected to the appropriate severity of cold as indication in the relevant specification. In the case of operational tests, a check is then made to ensure that the specimen is capable of operation. With the temperature maintained at the indicated value, the chamber air pressure is then reduced to the appropriate severity as specified in the relevant specification.

These conditions are maintained for the specified duration. Test profiles illustrating the procedure are shown in Figure 1a and Figure 1b. The chamber shall be capable of maintaining the conditions specified for Test Ab( for non-heat-dissipating specimen) or Test Ad(for heat-dissipating specimen) and for Test M. The requirement for the chamber wall temperature does not apply during periods of temperature or pressure change.

Care shall be taken to avoid air contamination by ancillary equipment and devices and by the air introduced when pressure is restored to normal. For the testing of a heat-dissipating specimen, the mounting of the test specimen shall comply with the requirements for Test Ad.

The severities, as indicated by temperature, air pressure and duration of exposure, shall be specified in the relevant specification. The temperature and low air pressure values, tolerances and durations shall be comply with those given in Test Ab or Ad and M. The duration of exposure shall be measured from the time when temperature stability of the specimen has been reached under conditions of low air pressure.

The specimen shall be visually inspected and electrically and mechanically checked as required by the relevant specification.

Heat-dissipating specimens shall be tested without forced air circulation in the chamber according to Test Ad. When the chamber used for testing is large enough to meet the conditions specified for Test Ad, but cooling of the chamber can only be carried out by forced air circulation, Method A of Test Ad may be applied.

Non-heat-dissipating specimens may be tested in a chamber with or without forced air circulation.

Heat-dissipating specimens shall be tested without forced air circulation in the chamber according to Test Ad. When the chamber used for testing is large enough to meet the conditions specified for Test Ad, but cooling of the chamber can only be carried out by forced air circulation, Method A of Test Ad may be applied.

Non-heat-dissipating specimens may be tested in a chamber with or without forced air circulation.

Procedure for heat-dissipating specimen without artificial cooling of the specimen and for non-heat-dissipating specimen is showed as below:

1. The chamber shall be at the temperature of the laboratory. The specimen at the ambient temperature of the laboratory shall be introduced into the chamber in the unpacked, switched off, “ ready for use” state, in its normal position or as otherwise specified.

2. The temperature within the chamber shall be adjusted to the temperature appropriate to the severity. The specimen shall be allowed to reach temperature stability. The rate of change of temperature within the chamber shall not exceed 1℃/min, averaged over a period of not more than 5 minutes.

3. For operation tests only. The specimen shall be switched on and checked to ascertain whether it is capable of functioning in accordance with the relevant specifications. The specimen shall then be switched off and allowed to reach temperature stability. The relevant specification may require another procedure for the check at low temperature and normal air pressure.

4. The pressure within the chamber shall be reduced to the value appropriate to the severity. The rate of change of pressure shall not exceed 100 mbar/min.

5. For operation only. The specimen shall be switched on or be electrically loaded. Checks shall be made to ascertain whether the specimen is capable of functioning in accordance with the relevant specification. The specimens may remain in the operating condition or be switched off as prescribed by the relevant specification.

6. The conditions of temperature and pressure shall be maintained for the specified duration.

7. For operational tests only. Intermediate measurements shall be performed during the final hour of the low pressure period in accordance with the relevant specification. The specimens shall be switched off or unload before the air pressure is restored.

8. The chamber pressure shall be restored to normal at a rate not exceed 100 mbar/min. During the increase of pressure, temperature control is not required .The specimen shall remain in the chamber and the temperature shall be gradually raised to a value lying within the limits of standard atmospheric conditions for testing. The rate of change of the temperature within the chamber shall not exceed 1℃/min averaged over a period of not more than 5 min.

9. The specimen shall then be subjected to the recovery procedure in the chamber or otherwise as appropriate.

1. The chamber shall be at the temperature of the laboratory. The specimen at the ambient temperature of the laboratory shall be introduced into the chamber in the unpacked, switched off, “ ready for use” state, in its normal position or as otherwise specified.

2. The temperature within the chamber shall be adjusted to the temperature appropriate to the severity. The specimen shall be allowed to reach temperature stability. The rate of change of temperature within the chamber shall not exceed 1℃/min, averaged over a period of not more than 5 minutes.

3. For operation tests only. The specimen shall be switched on and checked to ascertain whether it is capable of functioning in accordance with the relevant specifications. The specimen shall then be switched off and allowed to reach temperature stability. The relevant specification may require another procedure for the check at low temperature and normal air pressure.

4. The pressure within the chamber shall be reduced to the value appropriate to the severity. The rate of change of pressure shall not exceed 100 mbar/min.

5. For operation only. The specimen shall be switched on or be electrically loaded. Checks shall be made to ascertain whether the specimen is capable of functioning in accordance with the relevant specification. The specimens may remain in the operating condition or be switched off as prescribed by the relevant specification.

6. The conditions of temperature and pressure shall be maintained for the specified duration.

7. For operational tests only. Intermediate measurements shall be performed during the final hour of the low pressure period in accordance with the relevant specification. The specimens shall be switched off or unload before the air pressure is restored.

8. The chamber pressure shall be restored to normal at a rate not exceed 100 mbar/min. During the increase of pressure, temperature control is not required .The specimen shall remain in the chamber and the temperature shall be gradually raised to a value lying within the limits of standard atmospheric conditions for testing. The rate of change of the temperature within the chamber shall not exceed 1℃/min averaged over a period of not more than 5 min.

9. The specimen shall then be subjected to the recovery procedure in the chamber or otherwise as appropriate.

For more details, please feel free to contact sales@lenpure.com

Please visit www.lenpure.com