Climate Chambers for JASO M610 Cosmetic Corrosion Test Method

Lenpure Cycle Salt Spray Climate Chambers could evaluate the anti-corrosion ability of material and material coating , and make a comparsion about the product techniques and quality of similar coating and products , it be used to test the electronic elements, and metal materials and industrial products.

Model: 108L/270L/412L/663L/816L/1080

Apply to: CCT, NSS, ASS, CASS

Application: Hardware, Auto Parts, Construction Materials, Fastener

This standard specifies a method to examine cosmetic corrosion of material and surface treatment for automotive parts by cycle corrosion test.

Cosmetic corrosion

A corrosion phenomenon to damage parts appearance such as pitting and entire corrosion which is caused by such outside environmental factors as rain water, sunshine, and salt for melting snow.

Surface treatment

Such treatments as painting, plating, chemical treatment and anodization which are processed for decoration and anti-corrosion.

Cyclic corrosion test

A test in which a cyclic atmosphere consisting of salt water spraying, drying and wetting is repeated in order to approximate and activate a natural environment.

Type of test

The type of test shall be classified as Cyclic corrosion test.

Testing method

The testing method is such that a test piece prepared by a specified method shall be repeatedly exposed in a cyclic atmosphere consisting of salt spraying, drying and wetting maintained under a specified condition so as to evaluate cosmetic corrosions on a base metal and a surface treatment.

Test conditions

The preparation conditions and the test conditions shall be as shown in Table 1 and Table 2 respectively. As to the heating conditions in preparation, taking account of environmental conditions where the parts are used, they shall be deter mined as agreed upon between the purchaser and the manufacturer.

Test apparatus and instrument

(1) Test apparatus

The test apparatus to be required for this test shall consist of the salt spraying tower, tank of salt water for test, test piece holder, collecting container for sprayed solution, testing bath equipped with a temperature regulator, salt water supply tank, compressed air supplier humidifier, dry air supplier, exhauster and other necessary devices. The test apparatus shall satisfy to set up the specified test conditions as well as the conditions required as follows.

(a) The testing bath shall have capacity of 0.4 m3 and over. However, the shape and dimension have no restriction.

(b) The ceiling or top cover of the testing bath shall be so designed that the solution deposited on that place does not drop off onto the test piece.

(c) Corrosion resistive materials shall be used for the apparatus.

(d) The construction of the apparatus shall be so designed that the temperature and sprayed salt water in the testing bath shall not be influenced from the outside air, and the solution dropped from the test piece shall not be reused for further tests.

(e) The test piece holder shall hold the test piece at the specified angle.

(f) The collecting container for sprayed solution shall be a clean container having a horizontal collecting area of of 80 cm2 and located at least two positions where the uniformity of salt water spraying may be con firmed.For example, one is located at a place near the test piece, another is.located at a place near the salt water spraying tower, and the other is located at a place far away.

(g) The humidifier shall have a capability to set up to the specified wetting condition.

(h) The dry air supplier shall have a capability to set up to the specified drying condition.

(i) The exhauster shall be so designed that the salt water spraying is not influenced from the outside wind pressure.

(j) The maintenance control of the test apparatus shall be properly achieved so as to always obtain the specified conditions.

Point micrometer

This is an instrument to measure the position at which the plate thickness is decreased by corrosions, and it shall have capability to measure a range of 1/1000 mm. However, an alternative instrument may be used if it has capability to measure the equivalent range.

Tapes for masking

The tapes shall be used for masking a portion on a test piece where shall not be subjected to a test, thus it shall protect the masked portion from salt water and moisture, and shall be free from peeling off during a test. The polyester adhesive tapes conforming to the requirements specified in JIS C 2338.

Tapes for peeling-off

Cloth adhesive tapes specified in Js z 1524 having width of 25 mm or equivalent shall be used.

Cutter knife

A half side cutter made from SK2 specified in JIS G 4401 having width of approximately 18 mm shall be used.

Test piece

The test piece shall be a part itself or cut from a part. The numbers of test pieces shall be 3 per type.However, when they are not suitable for the test pieces because of their shapes or masses, test pieces of flat sheet may be used upon agreement between the purchaser and the manufacturer.

Cyclic corrosion test process

| Item | Conditions | |

|

1. Salt water spraying 2. Temperature 3. Density of salt |

35℃±1℃ 5±0.5% Others shall confirm to JIS Z 2371 |

|

|

1. Drying 2. Temperature 3. Relative Humidity |

60℃±1℃ 20~30%RH |

|

|

1. Wetting 2. Temperature 3. Relative Humidity |

50℃±1℃ 95%RH and over |

|

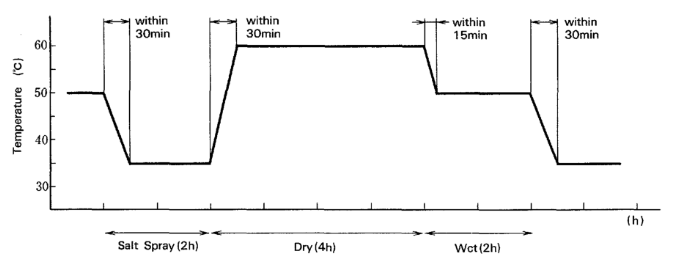

| 4. Duration and content per cycle |

8h Salt spraying: 2 hours Drying: 4 hours Wetting: 2 hours (including time for each change respectively) |

|

|

5. Time required in changing condition (Time required to reach the temperature and relative humidity specified for that conditions after changing to the condition) |

From spraying to drying: within 30 minutes From drying to wetting: within 30 minutes From wetting to spraying: within 30 minutes |

|

6. Test pattern

|

||

| 7. Test piece holding angle | Evaluation face of test piece shall be held at an angle 15~20°to the vertical line | |

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or our company, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .