Model:101L/225L/504L/800L/1000/

Apply to:Ozone Aging Test

Application:Rubber Products,Leather,Canvas

Overview

Lenpure Ozone Aging Test Chamber Can be used to test rubber products with static tensile deformation, such as vulcanized rubber, thermoplastic rubber, cable insulating bush; expose the test specimens to the sealed air in the test chamber without light and with constant ozone concentration and constant temperature according to predetermined time, and then observe the cracks on test specimens’ surface and the degree of change of other properties to evaluate the rubber’s ozone aging resistance properties.

Feature

▪ PID programmable controller with LED touch screen display

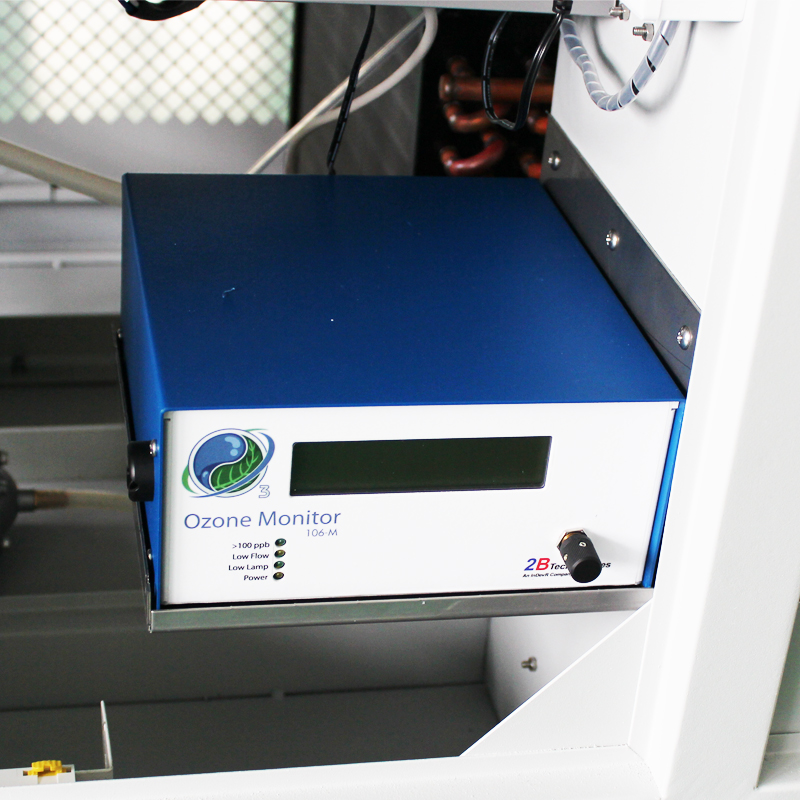

▪ Equipped with UV detector to detect the concentration of ozone

▪ Designed with combination of three control systems- PLC, HMI and SOC

▪Incorporated with protection module for safety voltage

▪ Franch - Techmesh Solid and durable structured closed-type compressor unit

▪ U.S ECO Consists of highly efficient low noise ozone generator

▪ Made up of corrosion resistant 316 stainless steel body

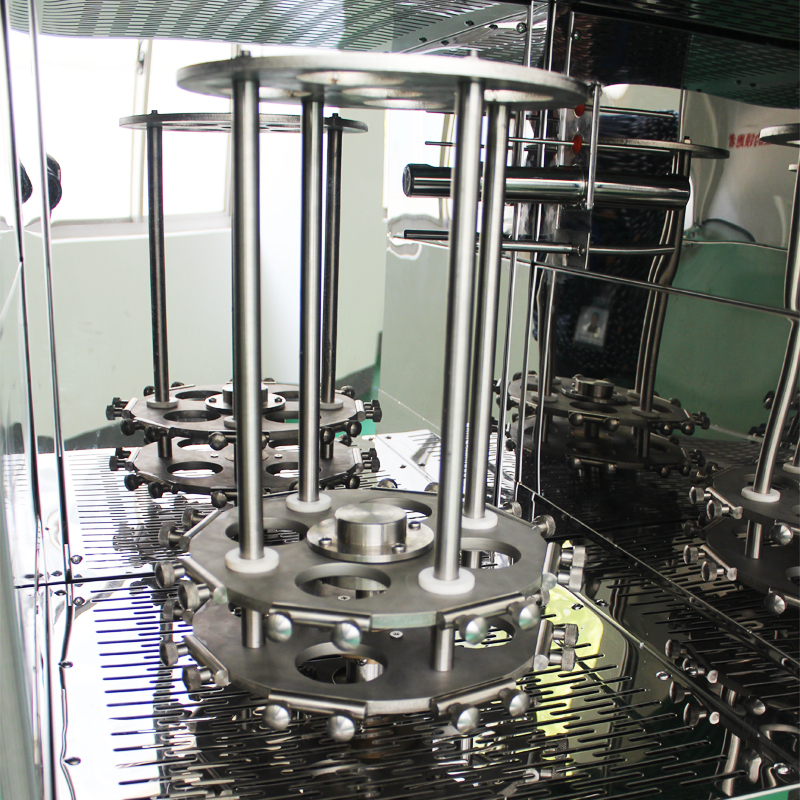

▪ Static & Dynamic sample holder are alternative

▪ Tri-color Indicator and EMO (Emergency-off Switch) available.

Test Standards

▪ ASTM D 1171 , ASTM D 1149

▪ DIN/EN 27326 , DIN 53509

▪ ISO 1431 , ISO 10960

▪ JIS K-6259

This test equipment comply with above test standards (but not limited to)

|

Model

|

Volume (L)

|

Temperature Range

(°C) |

Rated Power

|

Internal Dimension (mm) D*W*H

|

External Dimension (mm) D*W*H

|

|

LRHS-101-NO3

|

101

|

25°C ~ 65°C

|

4.0kw

|

450*450*500

|

1160*1000*1800

|

|

LRHS-225-NO3

|

225

|

5.5kw

|

500*600*750

|

1220*1150*2040

|

|

|

LRHS-504-NO3

|

504

|

7.0kw

|

700*800*900

|

1400*1350*2250

|

|

|

LRHS-800-NO3

|

800

|

9.0kw

|

800*1000*1000

|

1520*1540*2300

|

|

|

LRHS-1000-NO3

|

1000

|

11.5kw

|

1000*1000*1000

|

1720*1540*2300

|

|

| Basic Specification | |||||

|

Performance

|

Temperature Range | 25°C ~ 65°C | |||

| Temperature Fluctuation | ±0.5°C | ||||

| Temperature Uniformity | ≤ 2.0°C | ||||

| Temperature change speed | ± 2.0°C | ||||

| Humidity Range | 40% ~ 95% | ||||

| Humidity Deviation | +2 / -3% R.H | ||||

| Ozone Concentration | 50~1000pphm or 50~300ppm | ||||

| Ozone Concentration Deviation | ≤ ±10% | ||||

| Air Flow Rate | 8~16mm/s | ||||

| Rotate speed | 1~3r/min(adjustment) | ||||

| Time Setting Range | 1~9999 h/m/s adjustable | ||||

|

Material

|

External Casing | Cold-rolled A3 (Q235) steel plates with plastics painted. | |||

| Interior Working Room | Stainless Steel Plates SUS304 with miror surface | ||||

| Heat Isolation | Polyurethane foams and fine glass fibres | ||||

| Illumination Lamp | Philips® one in per standard test chamber. | ||||

| Casters | 4pcs, with PU covered for protection. Height adjustable and direction universal. | ||||

| Viewing Window |

Multi-la |

||||

| Door | Manually operated sliding door with unlock button | ||||

|

Heating & Cooling System

|

Heater | Steipped Nickel-chromium Wire Heater | |||

| Compressor | Hermetically-sealed Techmesh® or semi-sealed Bitzer® or GEA® or equivalent compressors | ||||

| Cooling Method | Single or dual cooling (Air-cooled or Water-cooled) | ||||

| Refrigerant | R404A or R23 (eco-friendly) | ||||

| Condenser | Plate-type heat exchanger | ||||

|

Control System

|

Controller |

7" Programmable colorful touch-screen display LCD English Display Microcomputer integrated controller |

|||

| Temperature Sensor | Platinum Resistance.PT100Ω | ||||

| Standard Configuration | Test Chamber x 1, Specimen Holder platform x 1 | ||||

| Safety Protection | Power leakage protection/Compressor over-heat, over-load or over-current protection/Dry burning protection. | ||||

| Voltage | AC220V/380V/440V±10%, 50Hz/60Hz or as per requirement | ||||

| Ambient Enviromental for application | 5°C~+30°C ≤ 85% R.H | ||||

Copyright(c) Shanghai Linpin 2011-2017 | Terms and Conditions | Privacy Policy | 沪ICP备12029585号 | 沪网安备31011209000148号